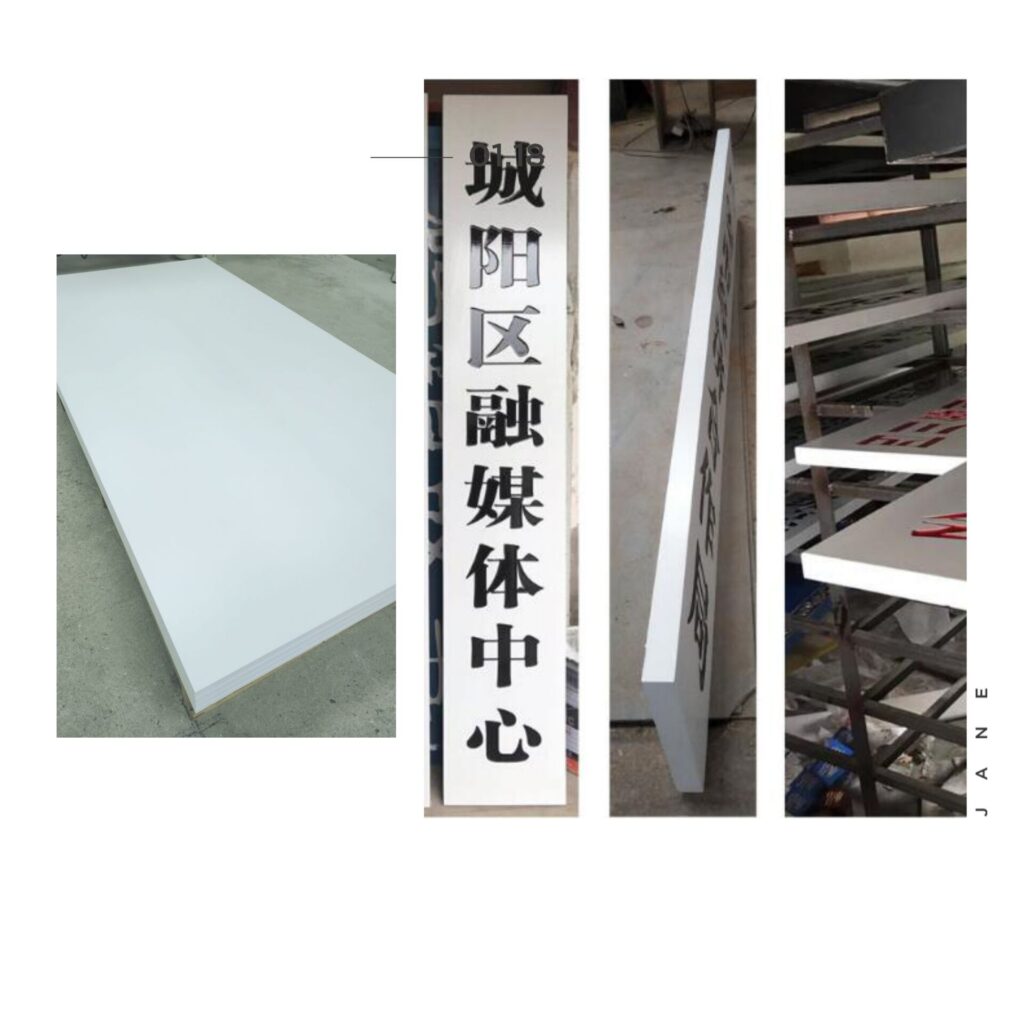

Today we are going to introduce how a common PVC billboard is made of PVC foam panel, which not only has good advertising effect but also has a cheap price price.

Cutting PVC foam panel

First we choose a piece of PVC foam panel with the size of 1.220mm*2440mm and thickness of 20mm, which is the regular size of PVC foam panel we can buy. The first step is to cut this PVC foam board into strips with a width of 35cm and a length of 200cm, which is the conventional size in billboard processing. If the customer has other requirements for the size of the board, it can be adjusted according to the customer’s needs. Next, choose a decal sheet, cut it slightly larger than the cut board and stick it on the surface of the PVC foam panel.

Engraving

The second part of the process is to open the engraving machine and place the board with the car sticker side up on the operating board of the engraving machine for engraving. The carving should use 1.5mm carving knife, so that the width of the carved texture is 1.5mm and the depth is 0.5mm. The knife can not be too deep, 3mm-5mm is a more appropriate depth.

Painting

After the engraving is finished, the part of the PVC foam panel with advertising letters stickers should be removed for painting and coloring. The last step of the process is painting, according to the customer’s requirements for the color of the hangtag word spray paint. The paint should be of good quality, and the paint should be strong in adsorption and not easy to fall off after drying, because the billboard should be exposed to outdoor for a long time, and the paint will affect the service life of the billboard if it falls off easily.