Introduction

PP hollow sheet, also known as polypropylene hollow sheet or PP corrugated sheet, is a lightweight and versatile material used in various industries. It is made of polypropylene plastic, which is a thermoplastic polymer known for its durability, high melting point, and resistance to chemicals, moisture, and UV radiation. PP hollow sheet is a type of corrugated plastic sheet that has two flat surfaces and a series of parallel ridges or flutes that run perpendicular to the flat surfaces.

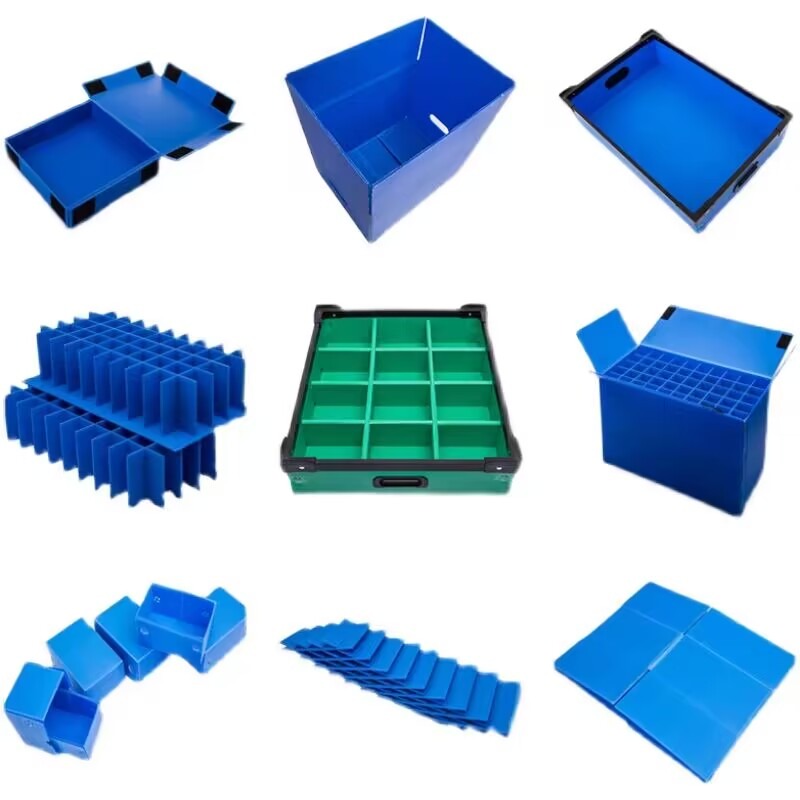

Classification and Applications

PP hollow sheet can be classified based on various factors such as thickness, density, color, and flute size. The thickness of PP hollow sheet can range from 2mm to 12mm, with 4mm and 6mm being the most common thicknesses. The density of PP hollow sheet can vary from low-density to high-density, with high-density sheets being more durable and resistant to impact. PP hollow sheet is available in various colors, including white, black, blue, red, and yellow, among others. The flute size of PP hollow sheet can be small or large, depending on the intended

Application.

PP hollow sheet has a wide range of applications across various industries such as packaging, advertising, construction, agriculture, and automotive. In the packaging industry, PP hollow sheet is used to make boxes, crates, trays, and partitions, among other products. In the advertising industry, PP hollow sheet is used to make signs, displays, and exhibition panels. In the construction industry, PP hollow sheet is used to make roofing, wall cladding, and insulation boards. In the agriculture industry, PP hollow sheet is used to make greenhouse panels, seedling trays, and livestock pens. In the automotive industry, PP hollow sheet is used to make interior trims, floor mats, and door panels.

Factors that Determine the Quality of PP Hollow Sheet

The quality of PP hollow sheet is determined by various factors such as the raw material used, the manufacturing process, the thickness and density of the sheet, and the flute size. PP hollow sheet made from high-quality raw material is more durable and resistant to wear and tear. The manufacturing process used to make PP hollow sheet can affect its strength, flexibility, and surface finish. The thickness and density of the sheet determine its stiffness, impact resistance, and load-bearing capacity. The flute size of PP hollow sheet affects its insulation properties, weight, and printing quality.

Applications of Different Quality PP Hollow Sheet

PP hollow sheet of different qualities can be used for various applications. Low-density PP hollow sheet is suitable for applications that require a lightweight and cost-effective material, such as temporary signage, displays, and packaging. High-density PP hollow sheet is suitable for applications that require a strong and durable material, such as reusable packaging, protective covers, and construction boards. Thick PP hollow sheet is suitable for applications that require a high load-bearing capacity, such as floor protection, traffic signs, and advertising boards. Thin PP hollow sheet is suitable for applications that require a high printing quality, such as graphics, displays, and promotional materials.

How to Choose and Purchase PP Hollow Sheet

When choosing and purchasing PP hollow sheet, it is essential to consider the intended application, the required thickness and density, the color and printing quality, and the cost. It is recommended to choose a PP hollow sheet that is appropriate for the application in terms of thickness, density, and flute size. The color and printing quality of the sheet should be selected based on the branding and design requirements. The cost of the sheet should be compared with other materials to ensure that it is cost-effective for the intended application.

Conclusion

PP hollow sheet is a versatile and cost-effective material used in various industries for different applications. It is available in different thicknesses, densities, colors, and flute sizes,